| Availability: | |

|---|---|

| Quantity: | |

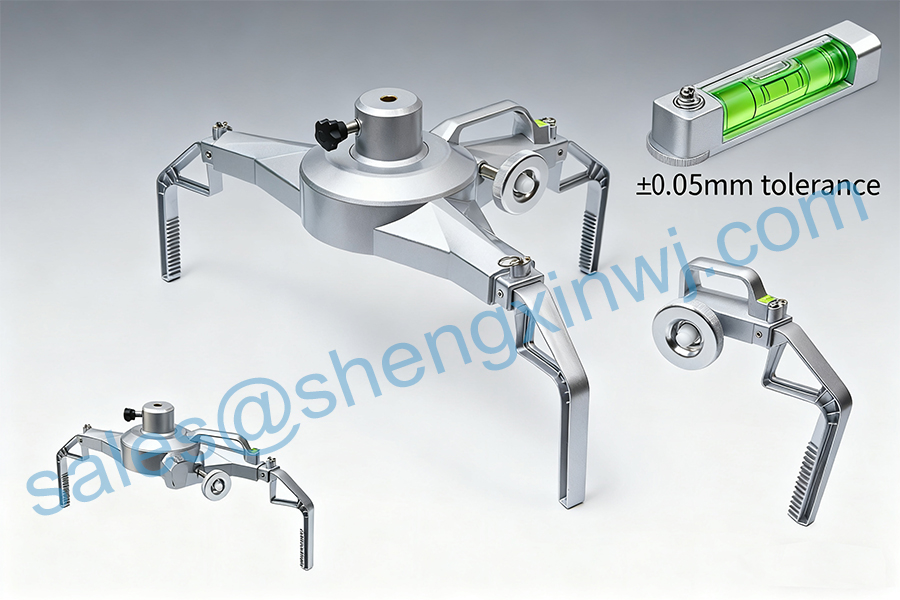

Quality wheel clamp supplier, ISO certified wheel clamps, reliable alignment accessories

Every Master three point wheel alignment Clamp undergoes stringent, multi-stage inspections. Discover our ISO-certified quality process and why leading brands choose us as their supplier.

Quality is not an afterthought; it is engineered into every step of our manufacturing process. The Precision Master Clamp Kit is subject to a closed-loop quality control system that guarantees absolute reliability.

Incoming Material Inspection: Every batch of raw aluminum alloy is verified for material grade and certification before entering production.

In-Process Checks: During CNC machining, critical dimensions are continuously monitored using digital calipers and micrometers to maintain tolerances within ±0.05mm.

100% Final Assembly Audit: Each assembled clamp is individually tested for smooth mechanism operation, spring tension, and structural integrity. No random sampling—every unit is inspected.

Performance Validation: A statistical sample from every production run is subjected to a cyclic load test, simulating years of shop use to validate long-term durability beyond the specified requirements.

This meticulous approach minimizes variability and ensures that when you integrate our clamps into your alignment systems, you are delivering a tool built to the highest standards of performance and safety.

Selecting a component supplier is a critical decision that impacts your product's reputation. Here is why professional alignment equipment manufacturers worldwide partner with us:

Decades of Specialized Focus: We are not a general accessory manufacturer. Our entire operation is dedicated to the engineering and production of wheel alignment accessories. This deep focus translates into superior product knowledge and unmatched expertise that you can rely on.

Proactive Engineering Support: We offer more than just products. Our technical team is available to collaborate on integration challenges, review design modifications, and provide CAD models for a seamless fit with your specific systems.

Proven Supply Chain Reliability: Our vertically integrated manufacturing and streamlined logistics ensure on-time delivery and consistent supply, protecting your production schedules from unexpected disruptions. We are a partner you can count on for the long term.

Don't just take our word for it. Access our material compliance reports, and detailed quality control protocols to see the documentation that backs our commitment.

[ Download Our Quality Certificates ] : download certificates

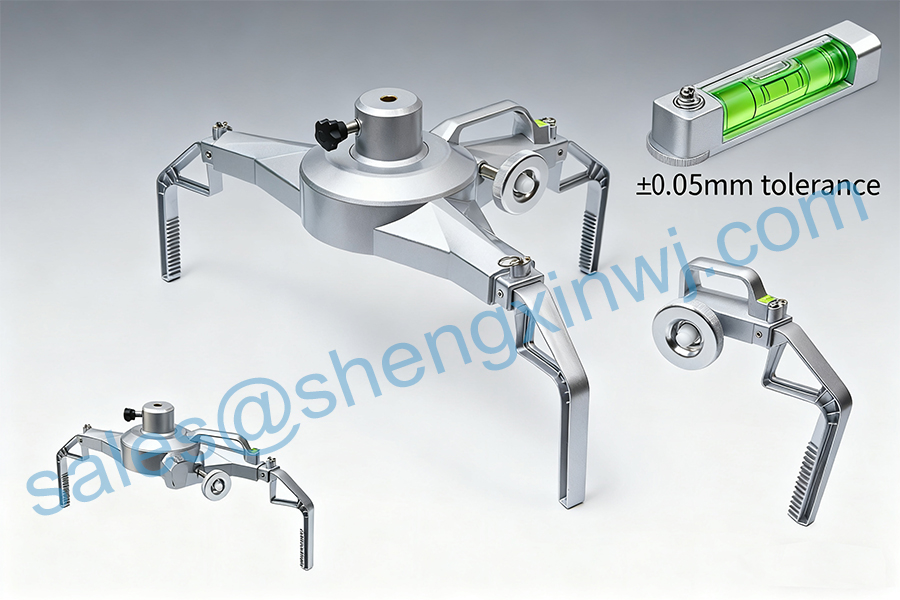

Quality wheel clamp supplier, ISO certified wheel clamps, reliable alignment accessories

Every Master three point wheel alignment Clamp undergoes stringent, multi-stage inspections. Discover our ISO-certified quality process and why leading brands choose us as their supplier.

Quality is not an afterthought; it is engineered into every step of our manufacturing process. The Precision Master Clamp Kit is subject to a closed-loop quality control system that guarantees absolute reliability.

Incoming Material Inspection: Every batch of raw aluminum alloy is verified for material grade and certification before entering production.

In-Process Checks: During CNC machining, critical dimensions are continuously monitored using digital calipers and micrometers to maintain tolerances within ±0.05mm.

100% Final Assembly Audit: Each assembled clamp is individually tested for smooth mechanism operation, spring tension, and structural integrity. No random sampling—every unit is inspected.

Performance Validation: A statistical sample from every production run is subjected to a cyclic load test, simulating years of shop use to validate long-term durability beyond the specified requirements.

This meticulous approach minimizes variability and ensures that when you integrate our clamps into your alignment systems, you are delivering a tool built to the highest standards of performance and safety.

Selecting a component supplier is a critical decision that impacts your product's reputation. Here is why professional alignment equipment manufacturers worldwide partner with us:

Decades of Specialized Focus: We are not a general accessory manufacturer. Our entire operation is dedicated to the engineering and production of wheel alignment accessories. This deep focus translates into superior product knowledge and unmatched expertise that you can rely on.

Proactive Engineering Support: We offer more than just products. Our technical team is available to collaborate on integration challenges, review design modifications, and provide CAD models for a seamless fit with your specific systems.

Proven Supply Chain Reliability: Our vertically integrated manufacturing and streamlined logistics ensure on-time delivery and consistent supply, protecting your production schedules from unexpected disruptions. We are a partner you can count on for the long term.

Don't just take our word for it. Access our material compliance reports, and detailed quality control protocols to see the documentation that backs our commitment.

[ Download Our Quality Certificates ] : download certificates